| ¡¡ | SS Multi Cartridge Filter Housing | Sand & Carbon Vessels | ¡¡ | ¡¡ | ¡¡ | ¡¡ |

| ¡¡ | SS Bag Filter Housing | UPVC Filter Housing | ¡¡ | ¡¡ | ¡¡ | ¡¡ |

| ¡¡ | Water Treatment Series | Swimming Pool Series | Bag Filter Housing | ¡¡ |

| Cartridge Filters for Swimming Pool | |||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

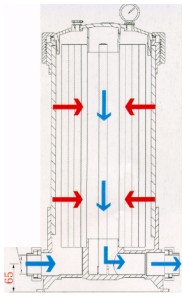

| INSTALLATION |

|

||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

| START UP PROCEDURE |  |

||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

| CLEANING AND CHANGE | ¡¡ | ||||||||||||||||||||||||||||||

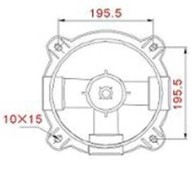

| When the filter gauage reading is 50 Kpa above the clean filter gauage reading, Cleaning the element is required. | PEDESTAL LOCATION |

||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||